A Comprehensive Overview to Different Sorts Of Galvo Scanners and Their Applications

Galvo scanners, known for their rate and precision, are essential to a variety of markets from manufacturing to clinical technology. The trip to selecting the optimum galvo scanner for your operational requirements begins with recognizing these nuances.

Basic Introduction of Galvo Scanners

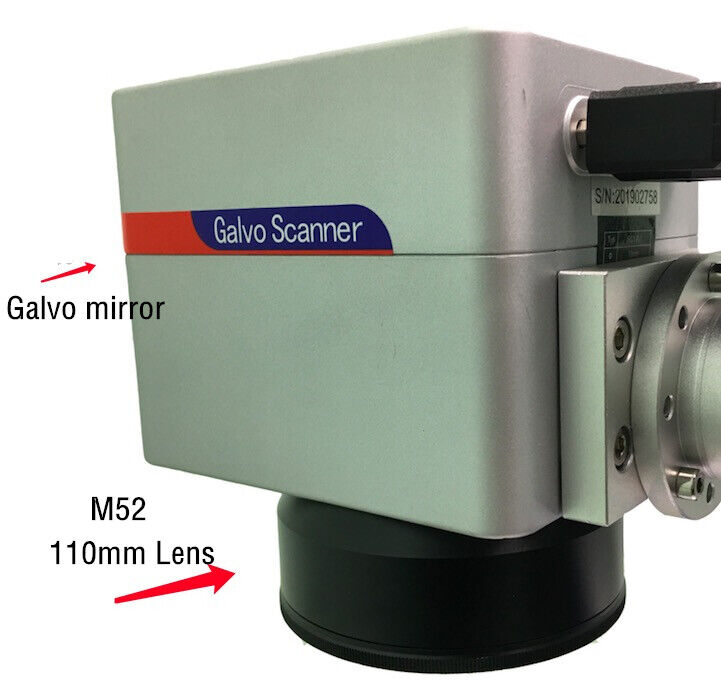

Galvo scanners, brief for galvanometer scanners, are accuracy devices made use of to guide laser beams properly and rapidly across an assigned location. Fundamentally, a galvo scanner is composed of a small, light-weight mirror attached to a galvanometer, which is an electromechanical gadget that determines electric present by deflection of a needle.

The core concept behind galvo scanners is the exact and quick control of the mirror's angle, which consequently transforms the instructions of the laser beam of light. This is achieved with a closed-loop responses system that guarantees the mirror's setting is constantly monitored and adjusted for accuracy. The feedback system makes up setting sensing units, control electronic devices, and high-performance motors, supplying extraordinary responsiveness and accuracy.

Galvo scanners stand out in applications calling for intricate and repeated laser motions, such as laser inscription, reducing, and clinical imaging. Their capacity to run at high speeds without sacrificing accuracy makes them important in scenarios requiring both performance and precision.

Kinds Of Galvo Scanners

When discovering the kinds of galvo scanners, it's vital to comprehend that variants are mostly based on their style, application needs, and performance requirements. Usually, galvo scanners can be categorized into single-axis and dual-axis versions.

Dual-axis galvo scanners, on the various other hand, supply two-dimensional control of the light path. This makes them essential in even more complex applications like laser light shows, 3D printing, and medical imaging. Dual-axis designs are commonly geared up with 2 mirrors and matching galvanometers, enabling dynamic control over both X and Y coordinates.

Secret Attributes to Take Into Consideration

Several vital functions should be meticulously assessed when selecting a galvo scanner for your specific application. Rate is an essential quality, as it identifies the scanner's capacity to deal with high-frequency jobs efficiently. The speed is typically determined in terms of action time and the maximum number of factors per second the scanner can address.

Another essential function is the scanner's series of activity, which shows the optimum angular inconsistency it can achieve. A broader array gives higher adaptability yet might call for much more innovative control systems. Thermal security likewise requires attention, as temperature fluctuations can impact efficiency; thus, decide for scanners with robust thermal administration systems.

Industry-Specific Applications

In different markets, galvo scanners play an essential duty by enhancing accuracy and performance in specialized applications. In the medical area, galvo scanners are important to laser surgical treatments and sensory procedures, where high-speed, accurate light beam positioning is crucial. These devices allow minimally intrusive surgeries by specifically targeting cells, hence minimizing healing times and boosting patient outcomes.

In production, galvo scanners are vital for laser engraving, reducing, and welding. Their capacity to promptly and accurately direct laser beams makes certain great post to read top quality surfaces and elaborate outlining, which is essential for the manufacturing of complex parts in vehicle, aerospace, and electronic devices industries. The textile industry also benefits from galvo scanners in fabric cutting and inscription, supplying both speed and precision in processing varied materials.

Choosing the Right Galvo Scanner

Choosing the appropriate galvo scanner is a critical decision that rests on several crucial variables, consisting of application requirements, performance specs, and budget restraints. Initially, clearly define the application demands. Whether the scanner is planned for laser engraving, clinical imaging, or 3D printing, each application requires details performance attributes such as resolution, accuracy, and speed.

Second, think about the performance specs. Specifications like check angle, reaction time, and thermal stability are essential (galvo scanner). A high-speed galvo scanner with a broad check angle is ideal for large-area marking, while applications requiring fine detail may prioritize high resolution and precision

Third, make up budget restraints. High-performance galvo scanners come with a substantial investment, but their lasting benefits can exceed initial expenses. Examine the total cost of ownership, including upkeep, to make certain the picked scanner supplies value over its life expectancy.

Conclusion

Recognizing the varied sorts of galvo scanners and their unique capacities is important for maximizing performance throughout various sectors. Single-axis and dual-axis designs accommodate various functional intricacies, while high-speed and high-precision variations address specific demands in manufacturing, fabrics, medical areas, and 3D printing. Careful option based upon the one-of-a-kind attributes and application requirements of each type of galvo scanner guarantees improved performance and precision, consequently considerably enhancing overall operational end results.

Galvo scanners, brief for galvanometer scanners, are precision devices utilized to route laser light beams properly and rapidly throughout a marked area.When checking out the types of galvo scanners, it's vital to understand that variations are largely based on their style, application demands, and performance requirements. Each kind click of galvo scanner is therefore distinctively tailored to satisfy specific operational needs, guaranteeing optimal efficiency across numerous applications.

The accuracy of a galvo scanner straight impacts the top quality of the outcome, making it important to consider the scanner's capability to preserve high-resolution performance (galvo scanner). Careful choice based on the distinct functions and application requirements of each kind of galvo scanner ensures enhanced efficiency and precision, thus dramatically boosting total functional end results